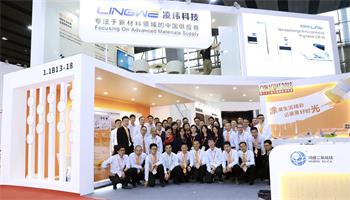

About Lingwe

Lingwe Technology Co., Ltd. is a modern industrial group integrating multi-functional silicon dioxide research and development, production, sales and technical services. It is the standard bearer of China’s matting agent industry. Its production base is one of the three major inorganic silicon production bases in China. - Hunan 3A New Material.

more>>

Media

Lingwe Technology Co., Ltd. is a modern industrial group integrating multi-functional silicon dioxide research and development, production, sales and technical services. It is the standard bearer of China’s matting agent industry. Its production base is one of the three major inorganic silicon production bases in China. - Hunan 3A New Material.

more>>

Join Us

You will have: high quality development platform, comfortable office environment, pleasant working atmosphere, excellent superior leaders, loving partners;

You will gain: rich work experience, rapid ability to improve, broad work vision, perfect promotion system;

You will enjoy: sound welfare mechanism, unexpected surprises, such as: generous bonuses, equity incentives, colorful staff activities......

more>>

You will gain: rich work experience, rapid ability to improve, broad work vision, perfect promotion system;

You will enjoy: sound welfare mechanism, unexpected surprises, such as: generous bonuses, equity incentives, colorful staff activities......

Share the: